Exhibitor Article

Dairy Automation Pvt. Ltd.

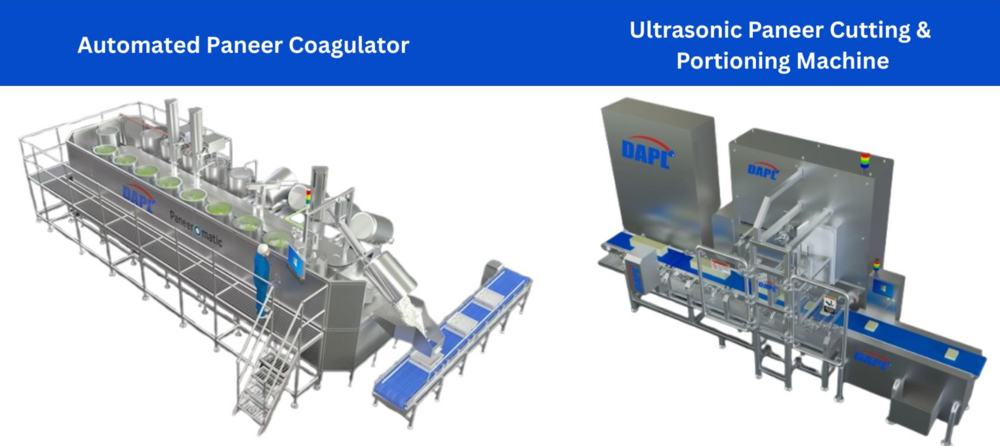

DAPL: Redefining Paneer and Cheese Manufacturing

For over two decades, Dairy Automation Pvt. Ltd. (DAPL) has been transforming paneer and cheese manufacturing through innovation, precision, and automation. From its early years, DAPL identified key challenges faced by the dairy industry—inconsistent product quality, labour-intensive operations, and low yields—and set out to address them with advanced engineering-led solutions.

One of DAPL’s most significant breakthroughs was the development of FDA-certified micro- perforated moulds, now globally recognised as a benchmark in paneer and cheese production. These moulds ensure efficient whey drainage, superior texture, and consistent quality, enabling dairies to achieve higher yields and uniform output. Today, DAPL is among only four companies worldwide manufacturing these specialised moulds, reinforcing its leadership in this segment.

Continuing its innovation journey, DAPL introduced the patented Automated Rotary Coagulator with multiple rotating vats—a world-first technology based on the “One Vat – One Mould” principle. This system ensures uniform coagulation, continuous production flow, and minimal manual intervention, significantly improving hygiene, efficiency, and scalability for paneer and cheese manufacturers.

What truly differentiates DAPL is its strong in-house ecosystem. The company operates a full- fledged manufacturing facility supported by an experienced in-house production team, ensuring complete control over quality, precision, and delivery timelines. Complementing this is a dedicated design and engineering team capable of developing customised solutions aligned to each dairy’s capacity, layout, and process requirements—allowing DAPL to deliver

bespoke systems rather than standardised equipment.

DAPL’s impact is reflected in its strong partnerships with leading dairy brands such as Amul, Banas Dairy, Hatsun, Heritage, and Lactalis. By helping these organisations shift from manual dependency to efficient, automated production, DAPL has played a key role in improving operational consistency, productivity, and output quality.

With a holistic approach, DAPL goes beyond supplying machinery—it transforms entire production operations. Every solution is designed to integrate seamlessly into existing processing lines, reduce wastage, enhance productivity, and maintain the highest standards of hygiene. International certifications including CE, ISO 22000, ROHS2, and FDA further reinforce DAPL’s commitment to quality, safety, and global compliance.

With successful projects across India, Australia, the UK, the USA, Kazakhstan, Canada, Uganda, and more, DAPL combines patented technologies, engineering excellence, and deep industry expertise to address real-world dairy processing challenges. Its comprehensive services—ranging from training and preventive maintenance to PLC-enabled monitoring and long-term technical support—ensure reliable and uninterrupted operations for its customers.

Conclusion

By identifying industry gaps, developing world-first innovations, and delivering customised, automated, and hygienic solutions through strong in-house capabilities, DAPL continues to set new benchmarks in paneer and cheese manufacturing worldwide. Discover how DAPL’s advanced automation solutions can help transform your dairy operations. Visit DAPL at Anuga FoodTec India Dairy - Booth no. D11 and explore technologies

designed for higher yields, consistency, and scalable growth.

To participate at the trade fair please fill in our EXHIBITOR ENQUIRY form and our sales team

will connect with you. To register as a visitor to attend the expo, kindly fill in our VISITOR

REGISTRATION FORM.